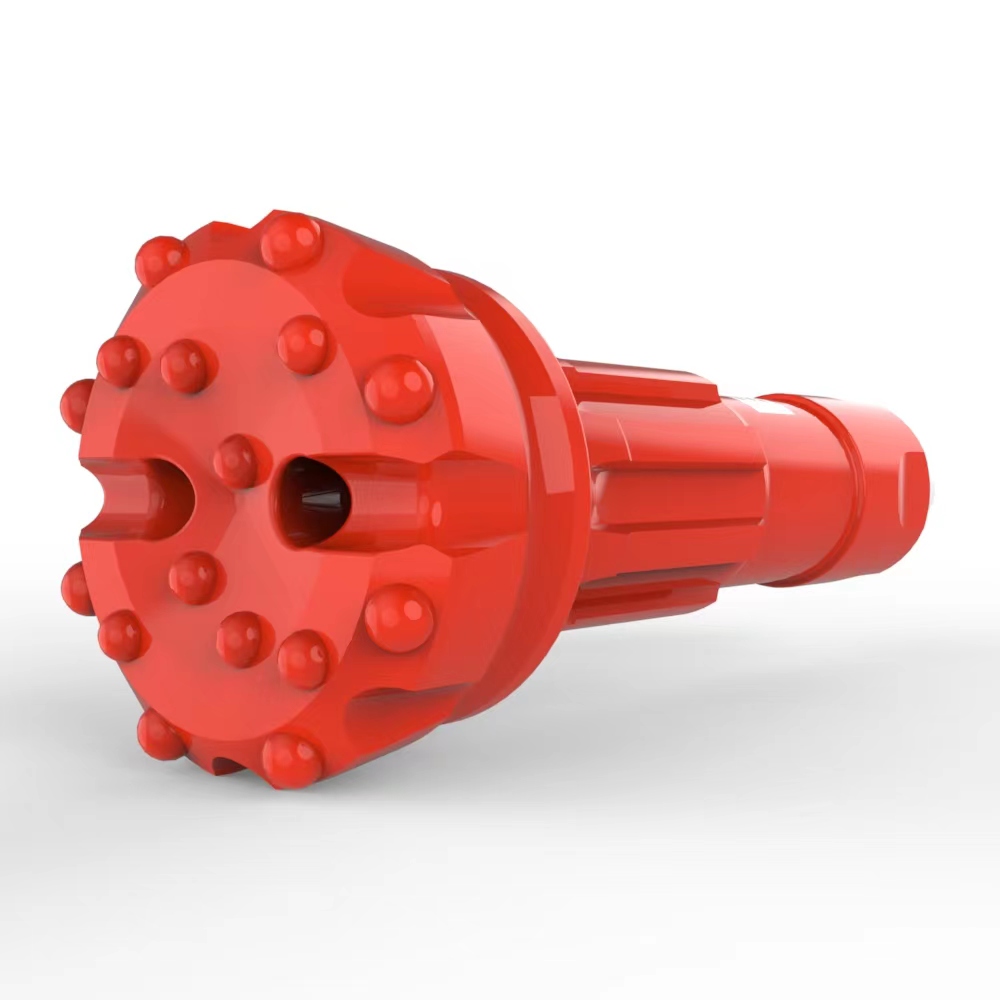

Hole Drilling Bits

Strong adaptability: A set of equipment can cover various rock formations from medium hard to extremely hard by replacing different models of hammers and drill bits, reducing equipment investment.

Good guidance: Since the hammer follows the drill bit, its longer cylindrical structure plays a good guiding and stabilizing role in the hole, which can effectively reduce the deviation of the drilling hole and is particularly suitable for drilling deep straight holes.

Strong impact force: It can provide a very large single impact energy and easily break hard and abrasive rocks

Product Description:

The Hole Drilling Bits is a core component of a down-the-hole drilling system and a highly efficient, specialized rock drilling tool. Used in conjunction with a down-the-hole hammer, it is designed specifically for drilling large-diameter, deep, straight blastholes and other engineering holes in medium-hard to very hard rock formations. Its unique operating principle directly impacts the rock at the bottom of the hole, resulting in extremely high drilling efficiency and superior drilling performance.

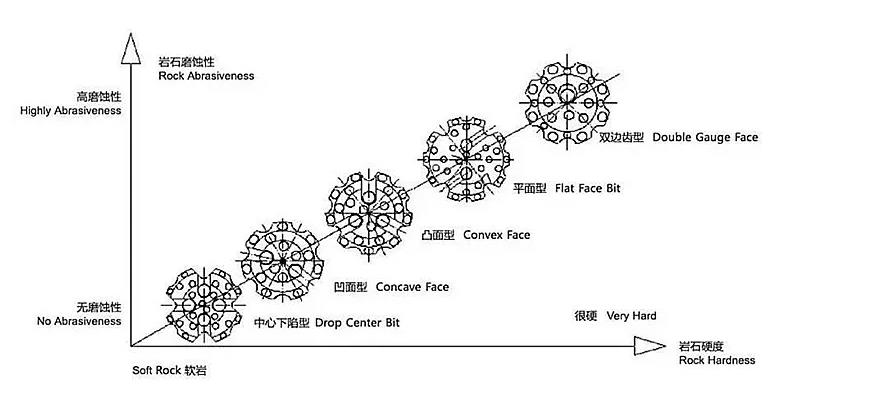

Bit face shape selection:

China high air pressure mining button hard rock dth hammer drilling bits water well

1. Drop Center Bit For high penetration rates in soft to medium hard and corrosive rock formations. Low to medium air pressures.Maximum hole deviation control.

2. Concave Face

The all-round application bit face specifically for medium hard and homo generous rock formations. Good hole deviation control and good flushing capacity.

3. Convex Face

For high penetration rates in soft to medium-hard with low to medium air pressures. It is the most resistance to steel wash, and may reduce the load and wear on the gauge buttons, but poor hole deviation control.

4. Double Gauge Face

This kind of face shape is suitable for fast penetration rates in medium to hard rock formations. Designed for high air pressures and good resistance to steel wash step gauge bit.

5. Flat Face Bit

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures.Good penetration rates an resistance to steel wash.

Specification of Hole Drilling Bits:

Our factory manufactures drill bits of various sizes, and also produces impactors and drill rods, please contact us if you need anything.

Packaging and Shipping:

Sturdy Packaging: High-strength plywood boxes offer strong load-bearing capacity, stable structure, and moisture- and leak-proof properties.

Convenient Customs Clearance: Packaging materials comply with international fumigation-free standards, simplifying import procedures and facilitating customs clearance.

Efficient Shipping: Shipments are completed within 7-15 business days after payment is received.

Hole Drilling Bits application industry

Open pit coal mines: Used for surface stripping and blast drilling before mining in coal mines, especially when encountering hard overburden rock.

Road cutting excavation: When building roads or railways in hilly areas, it is necessary to excavate tunnels or road cuttings through the mountains. Down-the-hole drill bits are used to drill slope pre-crack holes and main blasting holes.

Hydrological wells: Used for drilling deep water wells, especially in bedrock formations, and can efficiently penetrate hard rock formations to form wellbores with larger diameters and deeper depths.

Related News

Submitted successfully

We will contact you as soon as possible