Industrial Air Compressors: The All-Rounder That Drives Modern Manufacturing

Industrial air compressors are an indispensable power source for numerous industries. Their efficiency, reliability, and versatility have made them the invisible pillar of modern manufacturing. Whether it's precision operations on a production line or powering large-scale projects, air compressors play a key role. This article will delve into the wide range of applications for industrial air compressors, helping you better understand their value and find the right solution for your needs.

1. Manufacturing and Automated Production

In the manufacturing industry, air compressors power a variety of pneumatic equipment, such as robotic arms, assembly tools, and conveyor systems. Compressed air-powered equipment offers high precision, easy control, and low maintenance, making it widely used in industries such as automotive manufacturing, electronic equipment production, and home appliance assembly. Through stable power output, companies can improve production efficiency, reduce energy consumption, and achieve automation upgrades.

2. Food and Beverage Industry

In food and beverage production, compressed air is commonly used in packaging, filling, and cleaning processes. For example, pneumatic equipment helps quickly seal food bags, and compressed air is used to drive filling machinery, ensuring precise filling of liquid products. Furthermore, many food processing facilities rely on compressed air to control valves and transport raw materials, ensuring a hygienic and efficient production process.

3. Pharmaceuticals and Medical Equipment

The pharmaceutical industry places extremely high demands on air quality and stability. Compressed air is used to control cleanroom environments, drive packaging machinery, and operate laboratory instruments. Sterile compressed air is also used for pharmaceutical filling and to power medical equipment, ensuring that products meet stringent safety standards.

4. Energy and Chemicals

In the energy and chemical industries, compressed air is used to control valves, transport raw materials, and drive large machinery. For example, in petrochemical plants, compressed air supports automated control systems, improving operational safety and efficiency. Renewable energy projects, such as wind power and water treatment facilities, also rely on air compressors to perform critical tasks.

5. Construction and Mining

In the construction and mining industries, large air compressors power rock drills, crushers, and excavation equipment. Compressed air tools operate reliably in harsh environments, helping to accomplish tasks such as tunneling, mining, and infrastructure construction. Their durability and high efficiency make them a top choice for heavy-duty construction.

6. Transportation

In the transportation sector, compressed air is used in train braking systems, automotive painting, and marine equipment. For example, rail transit relies on compressed air to control doors and brakes, while auto repair shops use it to power spray tools and improve surface finishes.

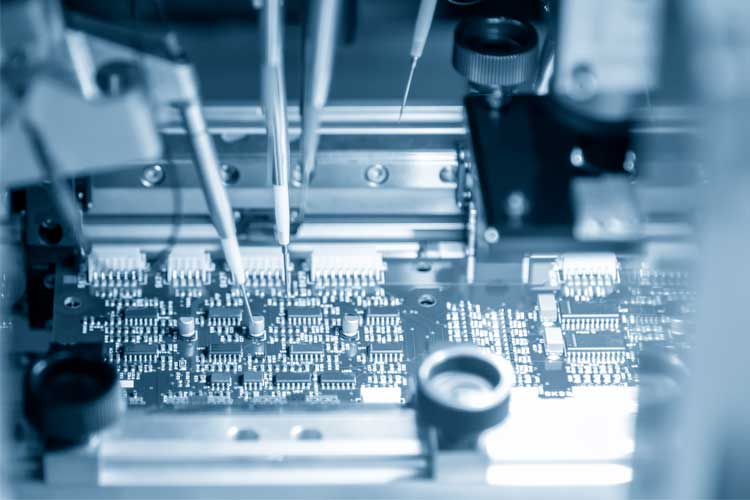

7. Electronics and Semiconductor Manufacturing

The electronics and semiconductor industries place extremely high demands on air purity and stability. Compressed air is used to control precision instruments, clean production lines, and maintain a dust-free environment. Efficient compressed air systems can reduce production failures and ensure product quality.

In conclusion

The application scenarios of industrial air compressors are far more than this, covering almost all industries that require power, control or automation support. Choosing the right compressor can not only improve production efficiency, but also reduce long-term operating costs. Whether it is energy-saving transformation, equipment upgrade or customized solution, professional technical support and service are essential.

Act now and give your business a strong boost!

Fill out the form or contact us now to receive exclusive services:

Free On-site Air Audit: Evaluate your current system to identify energy waste and potential risks.

Customized Solution Design: Customize an efficient and reliable compressed air solution for you.

Reference Case Studies: Explore successful applications in your industry.