Hydraulic Water Well Drilling Machine For Sale

1, Hydraulic Water Well Drilling Machine is a excessive efficiency and multi-functional down the hole water nicely drilling equipment, It can be used to drill water well,

agrecultural irrigation well, geothermal well and other kind well holes. It is sepcial suitable for mountain region and rock stratum water sourcing project.

2, Hydraulic Water Well Drilling Machine can drill in different stratum, The maximum bore diameter can be 350mm.

3, This computing device adopts big torque hydraulic motor for power head and manufacturer diesel, big diameter hydraulic cylinders for the hydraulic control system. The manufacturer diesel is protected by two levels air filtration systems and additionally can directly use the clean air from the air compressor.

4,Unique bump set graph and centralize controlled operation system is convenient to maintain and convenient for laptop operation.

5,This machine adopts excavator crawler chassis and make the machine a excessive off-road performance, It also can be mounted on a truck to make it extra maneuverability.

6, Two gears rotation and feeding speed makes it work in soil and rock layers.

Description of Hydraulic Water Well Drilling Machine

1, it is a excessive efficiency and multi-functional down the hole water properly drilling equipment, It can be used to drill water well,agrecultural irrigation well, geothermal well and other kind well holes. It is sepcial suitable for mountain place and rock stratum water sourcing project.

2, This machine can drill in different stratum, The most bore diameter can be 350mm.

3, This machine adopts big torque hydraulic motor for strength head and brand diesel, big diameter hydraulic cylinders for the hydraulic manipulate system. The brand diesel is protected by means of 2 levels air filtration structures and also can directly use the smooth air from the air compressor.

4,Unique bump set design and centralize controlled operation device is easy to maintain and handy for machine operation.

5,This machine adopts excavator crawler chassis and make the computing device a high off-road performance, It also can be set up on a truck to make it more maneuverability.

6, Two gears rotation and feeding speed makes it work in soil and rock layers.

Product display:

Product Specifications of Hydraulic Water Well Drilling Machine:

Application of Hydraulic Water Well Drilling Machine:

Geothermal power generation and heating: Drilling geothermal wells thousands of meters deep to extract high-temperature geothermal fluids (hot water or steam) for power generation or district heating.

Hydrogeological survey: Conduct preliminary groundwater condition survey and assessment for large-scale engineering construction projects (such as dams, nuclear power plants, and high-speed railways).

Environmental monitoring wells: Monitoring wells are drilled to regularly extract groundwater samples, analyze water pollution, and monitor the impact of potential pollution sources such as landfills and chemical plants on groundwater.

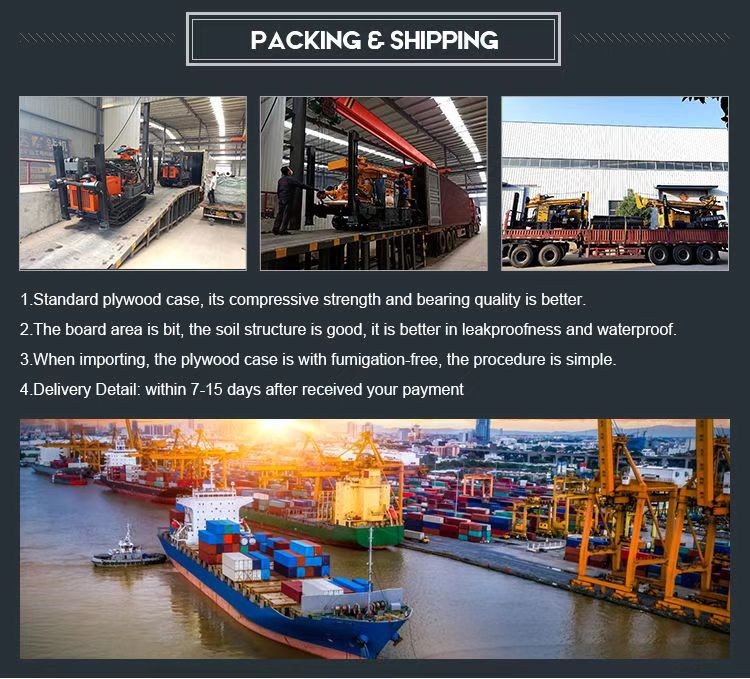

Packaging and Shipping of Hydraulic Water Well Drilling Machine:

Equipment inspection: Conduct a comprehensive inspection of all key components of the drilling rig (such as the power system, drill pipe, crawler tracks, etc.) to check for looseness, damage, or wear, to ensure that the entire machine is in good condition and can effectively withstand the bumps and vibrations that may occur during transportation.

Choose a transportation route: Plan a suitable transportation route based on the size, weight and other parameters of the drilling rig, avoiding sections with height and width restrictions and areas with poor road conditions to ensure safe and smooth transportation.

Customer visit:

Related News

Submitted successfully

We will contact you as soon as possible